Advancements in Precision Metal Bending

Introduction

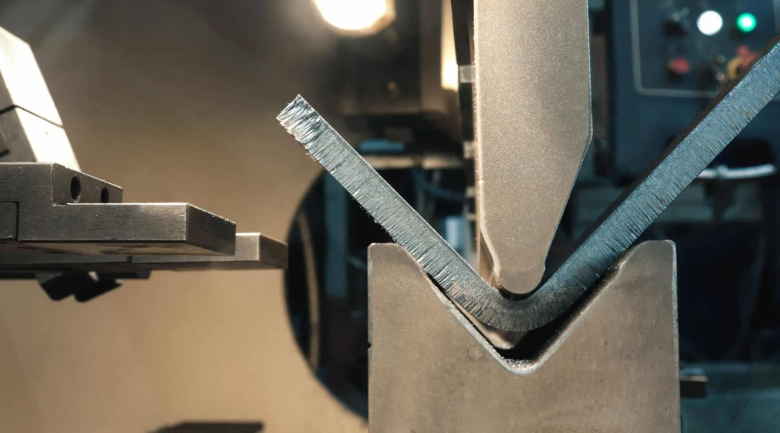

The metal fabrication industry has seen tremendous technological progress in recent years. Among the most impactful developments is the evolution of press brakes, which have become indispensable for manufacturers requiring precise bending operations. Modern machines offer high accuracy, repeatability, and efficiency, enabling businesses to handle increasingly complex projects with ease.

The Evolution of Press Brakes

Traditional press brakes relied heavily on manual operation and mechanical adjustments, which often resulted in inconsistencies and slower production speeds. With the introduction of CNC technology and multi-axis systems, manufacturers now enjoy greater control over every aspect of the bending process. Machines with multiple axes allow operators to fine-tune each movement, ensuring perfect angles and repeatable results.

What Makes Multi-Axis Machines Unique

An 8 axis press brake represents the pinnacle of modern bending technology. It provides independent control of various components, including back gauges, ram position, and tool alignment. This level of precision ensures that even complex geometries can be achieved without repositioning the workpiece multiple times.

Key Features

- Independent Axis Control: Adjustments can be made on multiple points simultaneously.

- CNC Programming: Predefined bending sequences reduce manual input and errors.

- Versatility: Suitable for different sheet metals and thicknesses.

- Safety Mechanisms: Modern systems include light curtains, emergency stops, and protective guards.

- Robust Design: Heavy-duty construction maintains stability during high-load operations.

These features collectively improve productivity and minimize waste.

Advantages Over Conventional Systems

Compared to traditional machines, advanced multi-axis press brakes offer numerous benefits:

- Precision: Multi-axis control guarantees consistent bending angles.

- Efficiency: Automated sequences speed up production.

- Reduced Waste: Accurate bends decrease scrap material.

- Operator Convenience: Less dependency on manual skill reduces errors.

- Consistency: Repeatable results ensure uniformity across large batches.

Manufacturers relying on these systems can achieve both high-quality output and operational efficiency.

Industrial Applications

The adoption of advanced press brakes has transformed multiple sectors:

- Automotive: Production of brackets, panels, and chassis components.

- Aerospace: Fabrication of lightweight and precision parts.

- Construction: Shaping structural components and metal enclosures.

- Electrical and Electronics: Bending control panels, housings, and sheet metal enclosures.

- Custom Fabrication: Ideal for prototyping and small batch production.

The versatility of machines like the 8 axis press brake allows them to be applied across a wide range of projects, from mass production to intricate custom parts.

See also: Smart Homes for Sale With Latest Tech Features

Why Multi-Axis Control Matters

An 8 axis press brake provides unique capabilities that enhance operational efficiency:

- Back Gauge Adjustments: Accurate placement of sheets for consistent bends.

- Independent Tool Alignment: Ensures proper positioning for complex geometries.

- Real-Time Corrections: CNC control allows adjustments during the bending process.

- Complex Forming: Multiple bends can be achieved without repositioning the material.

This multi-dimensional control reduces error rates and improves overall productivity.

Selecting the Right Machine

Choosing an appropriate press brake requires careful evaluation of multiple factors:

- Number of Axes: Determine how many independent axes are needed for your operations.

- Drive Type: Hydraulic, electric, or hybrid systems offer different performance levels.

- Software Capabilities: User-friendly CNC interfaces simplify programming and operation.

- Build Quality: A sturdy frame ensures longevity and consistent performance.

- Support and Maintenance: Reliable service ensures minimal downtime.

A machine tailored to your operational needs maximizes both efficiency and return on investment.

Maintenance Considerations

Proper upkeep is essential for maintaining performance and reducing downtime:

- Routine Inspections: Check hydraulic, electrical, and mechanical components regularly.

- Lubrication: Keep moving parts well-oiled to reduce wear.

- Software Updates: Ensure CNC systems are current to prevent operational issues.

- Operator Training: Skilled operators reduce the likelihood of errors and machine strain.

Consistent maintenance helps preserve accuracy and extends the lifespan of the equipment.

Economic Impact

Investing in advanced machinery has tangible financial benefits:

- Lower Material Costs: Accurate bending reduces scrap and rework.

- Faster Production: Automation accelerates throughput.

- Reduced Labor Costs: Less reliance on manual adjustments.

- High Reliability: Quality construction decreases maintenance expenses.

These advantages translate to higher efficiency and reduced production costs.

Future Trends in Metal Fabrication

Industry trends suggest continued innovation in press brake technology:

- Smart Manufacturing: Integration with IoT for real-time monitoring.

- Predictive Maintenance: Sensors anticipate issues before they cause downtime.

- Energy Efficiency: Electric and hybrid systems reduce energy consumption.

- Automation: Robotic loading and unloading streamline the workflow further.

These innovations are expected to enhance precision, efficiency, and cost-effectiveness.

Conclusion

Modern press brakes, especially multi-axis systems such as the 8 axis press brake, have transformed metal bending operations. They provide unprecedented accuracy, versatility, and automation, making them essential tools for manufacturers dealing with complex components. With proper machine selection, skilled operation, and regular maintenance, businesses can maximize productivity while maintaining high-quality standards. The ongoing evolution of these systems promises even greater efficiency and capability in the years ahead.