Enhancing Metal Fabrication Accuracy Through Advanced Control Systems

Introduction

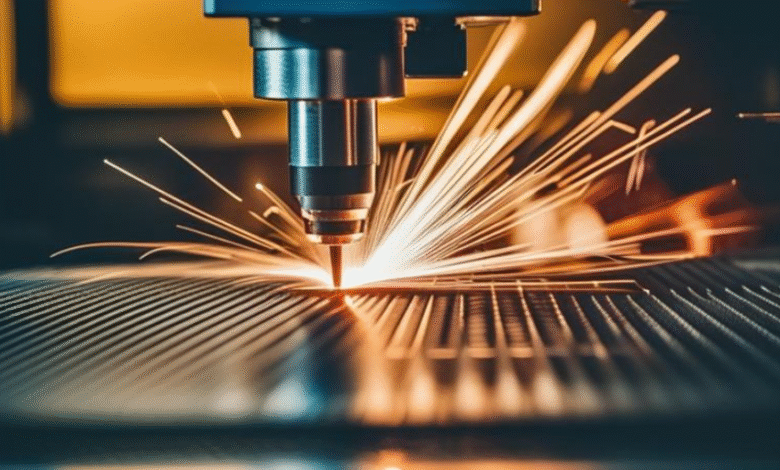

In modern manufacturing, precision and speed are essential to achieving high-quality production outcomes. Among the many machines used in metal fabrication, the press brake cnc back gauge plays a vital role in shaping and bending metal sheets accurately. This system not only improves productivity but also ensures repeatability and consistency in every operation. With the growing demand for automation and accuracy, such systems have become the backbone of efficient fabrication workshops.

Understanding the Function of the System

A press brake cnc back gauge is an integral part of a press brake machine that determines the position of the metal sheet before bending. It moves automatically to ensure that the metal is positioned at the correct distance from the bending edge. This level of automation eliminates the need for manual measurement and alignment, thus reducing human error. The back gauge system uses computer numerical control (CNC) technology to adjust its position with remarkable accuracy, ensuring that each bend is made exactly as programmed.

Components and Working Principle

The system typically consists of several major components: linear guides, ball screws, servo motors, and sensors. The servo motors are responsible for driving the back gauge to the programmed positions, while the sensors provide feedback to the CNC controller to verify the accuracy of movement.

When the operator enters the desired bending parameters, the CNC controller calculates the optimal back gauge position. As the metal sheet is fed into the press brake, the back gauge ensures that it is correctly aligned. Once in place, the bending process occurs with precise control over the angle and dimension.

See also: high tech smart homes available

Advantages of Using the System

The adoption of a press brake cnc back gauge offers multiple advantages in industrial applications.

- Increased Precision: The CNC-controlled movement ensures consistent results in repetitive bending operations.

- Higher Efficiency: Automation reduces the time spent on manual setup, allowing faster production cycles.

- Reduced Material Waste: Accurate positioning minimizes errors that could lead to material wastage.

- Enhanced Safety: Less manual handling reduces the risk of accidents during the bending process.

- Flexibility: The system allows easy adjustments to different bending dimensions through programming, making it suitable for various product designs.

Industrial Applications

This technology finds its place in a wide range of industries. Manufacturers in automotive, aerospace, and construction rely on it for creating precise metal components. The repeatable accuracy of the press brake cnc back gauge makes it ideal for producing parts such as brackets, panels, and enclosures. In the electrical industry, it helps fabricate switch boxes and control panels with perfectly aligned edges.

Comparison with Manual Systems

Traditional manual systems required constant adjustments by skilled operators. This process was time-consuming and prone to errors, especially in large production batches. In contrast, the automated system significantly enhances repeatability. Once programmed, it can perform thousands of identical bends without deviation. Moreover, while manual systems depend heavily on operator expertise, CNC-based systems provide consistent results regardless of operator skill level.

Maintenance and Performance Optimization

Proper maintenance of the press brake cnc back gauge ensures its longevity and reliability. Regular cleaning of guides and screws prevents dust buildup that may affect movement. Calibration checks are also essential to maintain alignment accuracy. Lubrication of moving parts and inspection of servo motor performance should be part of routine maintenance schedules.

Software updates also play a critical role in enhancing performance. Modern CNC systems frequently receive upgrades to improve efficiency and introduce new functionalities.

Future Trends in CNC Technology

As technology continues to evolve, the future of press brake cnc back gauge systems looks promising. Manufacturers are integrating artificial intelligence (AI) and machine learning (ML) to enable predictive maintenance and adaptive control. Smart sensors are being developed to automatically detect deviations and correct them in real-time. Furthermore, integration with cloud-based systems allows operators to monitor performance remotely and manage production data efficiently.

Environmental and Economic Impact

Adopting such automation not only benefits productivity but also contributes to sustainability. Reduced material waste directly minimizes environmental impact. Additionally, energy-efficient servo systems help reduce overall power consumption. From an economic standpoint, businesses achieve a faster return on investment due to reduced labor costs and improved throughput.

Conclusion

The press brake cnc back gauge stands as a symbol of precision engineering in modern metal fabrication. Its ability to deliver consistency, accuracy, and efficiency makes it indispensable for industries seeking high-quality output. As automation and intelligent technologies continue to advance, this system will only grow more sophisticated, paving the way for smarter, faster, and more sustainable manufacturing solutions.