Understanding the Cost Factors Behind Biaxial Mesh Applications

Introduction

In modern construction and civil engineering, geosynthetics play a vital role in improving ground stability and soil reinforcement. Among these, biaxial mesh is a widely used material that ensures long-term performance and cost efficiency. Understanding how the malla biaxial precio varies can help engineers, contractors, and buyers make more informed purchasing decisions. This article explores the major elements that influence the price, its applications, and how to choose the right type of biaxial mesh for your project.

What Is Biaxial Mesh?

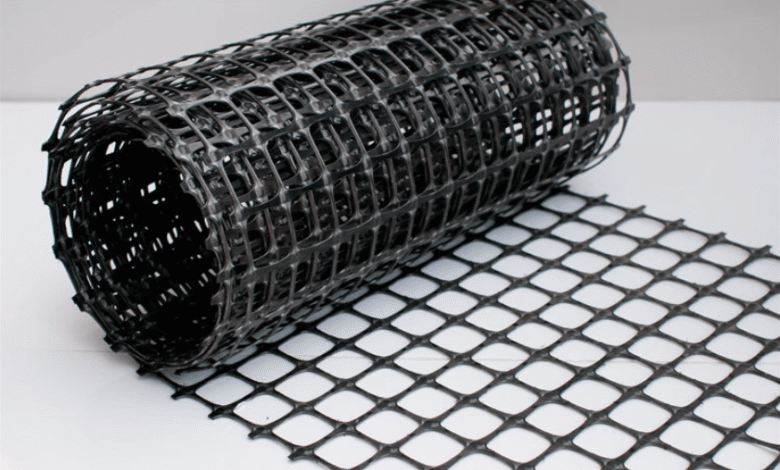

Biaxial mesh, commonly used in soil stabilization and pavement reinforcement, is made from high-strength polymers like polypropylene or polyethylene. The material is stretched in two directions—longitudinal and transverse—giving it balanced strength in both axes. This structure enhances the distribution of loads over a wider area, making it ideal for applications such as roadbeds, embankments, and retaining walls.

See also: Driving Business Growth Through Digital Optimization

Key Factors Influencing malla biaxial precio

The cost of biaxial mesh can differ based on several technical and logistical aspects. Some of the most important factors include:

1. Material Composition

The type and quality of raw material used to produce biaxial mesh significantly affect its cost. Mesh made from virgin polypropylene usually costs more than those made from recycled materials, as it offers superior durability and tensile strength.

2. Manufacturing Process

Advanced production technologies, such as precision stretching and thermal stabilization, add to the production cost but ensure better quality and longevity. Factories that follow strict quality standards may charge a higher malla biaxial precio due to added reliability.

3. Mesh Size and Strength

The mesh aperture size and the tensile strength directly influence its price. Smaller apertures and higher tensile strength meshes are more expensive because they require more polymer and precise engineering.

4. Market Demand and Supply

Like most construction materials, the price can fluctuate based on market trends, regional availability, and seasonal demand. During peak construction periods, demand for biaxial mesh typically increases, leading to a temporary price rise.

5. Transportation and Logistics

Freight costs, especially for bulk orders, play a big role in determining the total purchase price. Buyers located far from manufacturing plants or ports may incur higher transportation costs.

Applications of Biaxial Mesh

Biaxial mesh is highly versatile and used in various infrastructure and environmental projects. Understanding its application can help in estimating the right specifications and cost.

1. Road Construction

In road projects, biaxial mesh is placed under asphalt or gravel layers to distribute loads evenly and prevent rutting. Its use minimizes future maintenance costs and enhances road lifespan.

2. Railway Track Stabilization

For railway foundations, biaxial mesh prevents track deformation caused by heavy loads and soil movement. This improves train safety and track stability.

3. Retaining Walls and Embankments

Biaxial mesh is also essential in supporting retaining walls and embankments, especially on slopes. It reduces erosion and enhances the overall strength of the structure.

4. Airport Runways and Industrial Floors

In heavy-duty applications like airport runways and factory flooring, biaxial mesh helps maintain a stable surface, preventing cracks and deformation over time.

Benefits of Using Biaxial Mesh

Biaxial mesh offers numerous advantages that justify its cost and widespread use.

1. Improved Load Distribution

The dual-directional tensile strength allows for even load distribution, reducing stress on the subgrade layer.

2. Reduced Maintenance Costs

Using biaxial mesh extends the lifespan of roads and other structures, resulting in long-term savings.

3. Easy Installation

It is lightweight and flexible, allowing for quick installation with minimal labor and equipment.

4. Environmentally Friendly

Most biaxial meshes are made from recyclable materials, contributing to sustainable construction practices.

Comparing Prices Across Markets

When assessing the malla biaxial precio in different regions, it is important to compare both the cost and the technical specifications. Prices in Latin America, for instance, might differ from those in Asia due to manufacturing costs, import taxes, and local demand. Buyers should always consider certifications such as ISO or ASTM standards when evaluating suppliers, as these ensure consistent quality.

Tips for Selecting the Right Biaxial Mesh

Choosing the right mesh involves more than just looking at the price. Here are some important guidelines:

1. Assess Project Requirements

Determine the load-bearing needs and environmental conditions of your project before selecting a mesh type.

2. Check Product Specifications

Verify tensile strength, aperture size, and polymer type to ensure the mesh suits your intended application.

3. Source from Reputable Suppliers

Always purchase from trusted suppliers who provide certification and warranty. Cheap alternatives may lead to long-term failures.

4. Consider Installation Support

Some manufacturers offer technical assistance or installation services. These may increase initial costs but reduce the risk of errors during setup.

Future Trends in Biaxial Mesh Production

With ongoing technological advancements, the production of biaxial mesh is becoming more efficient and environmentally conscious. Manufacturers are focusing on lightweight, high-performance polymers and automated production systems to maintain consistent quality while lowering costs. These innovations are expected to stabilize the malla biaxial precio in the coming years.

Conclusion

Understanding the variables that impact the malla biaxial precio helps buyers and engineers make cost-effective choices without compromising on quality. Whether used for roads, railways, or retaining walls, biaxial mesh continues to be an essential material in the infrastructure industry. By focusing on quality, specification, and trusted suppliers, users can achieve both long-term durability and value for money.